RO Water plant Data Logger

Data Loggers

Overview

An RO Water Plant Data Logger is designed specifically for monitoring and managing the various parameters in Reverse Osmosis (RO) water treatment systems. These data loggers ensure that the RO plant operates efficiently, meets water quality standards, and maintains optimal performance. Here’s an overview of the key aspects and features of an RO Water Plant Data Logger

Key Features

1. Monitoring: Tracks critical parameters in the RO water treatment process, including pressure, temperature, flow rate, and water quality indicators.

2. Feed Pressure: Measures the pressure of the incoming water supply to the RO system.Feed Flow Rate: Measures the rate at which water enters the RO system.

3. Display: User interface for real-time visualization of data, including graphs, gauges, and numerical readouts.

4. Wired Interfaces: USB, Ethernet, and RS-232/RS-485 for data transfer and integration with other systems.

5. Software Tools: Provides analysis tools for trend analysis, statistical evaluations, and graphical representation of data.

6. Web-Based Access: Enables remote monitoring and management through web-based platforms.

7. Operating Conditions: Designed to operate in industrial environments with temperature ranges typically from -10°C to +60°C.

Specifications

1.Number of Channels: Typically 8 to 32 channels, depending on the model.

2.Analog Inputs: For connecting sensors measuring temperature, pressure, flow rate, and water quality.

3.Pressure : 0 to 1000 bar (0 to 14500 psi), adjustable based on sensor specifications.

4.Water Quality Range: 0 to 200,000 µS/cm for conductivity, or 0 to 100,000 ppm for TDS.

5. Display and User Interface: Display Type: 4.3" to 7" touchscreen TFT LCD. Graphical interface for easy navigation, data visualization, and system

6.Communication Interfaces:USB: For direct data transfer and device configuration.For network connectivity and remote access.

7.Threshold Alarms: Configurable high/low limits for each monitored parameter.

Who It's For

1.Water Treatment Facilities:To monitor and control the operation of the RO system, ensuring optimal performance and compliance with water quality standards.

2.Water Quality Managers: To ensure that treated water meets regulatory standards and to monitor the efficiency of the RO treatment process.

3.Facility Managers: In industries that rely on purified water, such as pharmaceuticals, electronics, and food and beverage, to maintain high water quality and system efficiency.

4.Environmental Scientists: For monitoring water treatment systems used in research projects and ensuring that water quality meets experimental requirements.

5.Project Engineers: Involved in the design and installation of RO water treatment systems to ensure that they meet specifications and performance standards.

How It Works

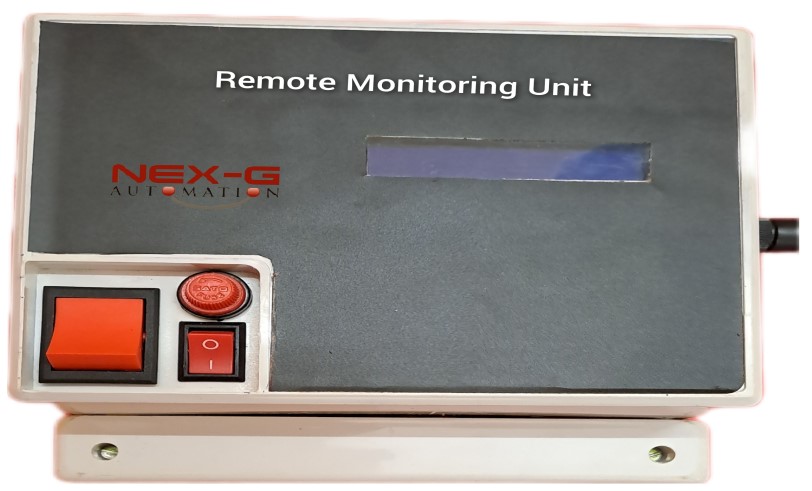

Placement: The data logger is installed at a central location within the RO system where it can connect to all relevant sensors and instruments. It should be situated in a location that is protected from extreme conditions but accessible for maintenance.

Initial Setup: Configure the data logger using its interface (physical or software). Set up the input channels for different sensors, configure sampling rates, and define measurement ranges.

Sensors: Sensors continuously measure the physical and chemical properties of the water. For example, pressure sensors measure the pressure at various points in the RO system, while temperature sensors monitor the temperature of the feed water and permeate.

Data Logging: The data logger stores sampled data in internal memory or on external storage devices such as SD cards or USB drives.

Interface: The data logger’s display provides real-time visualization of data, including graphs, gauges, and numerical readouts.Software Tools: Analysis tools, either built into the data logger or available via accompanying software, allow for detailed examination of recorded data, including trend analysis and statistical calculations.

Peace of Mind

An RO Water Plant Data Logger provides significant peace of mind to users by ensuring reliable operation, high-quality water production, and adherence to regulatory standards. Here’s how it contributes to operational confidence and security An RO Water Plant Data Logger offers peace of mind by providing comprehensive monitoring, early detection of issues, and detailed data analysis. It ensures reliable operation, regulatory compliance, and optimal performance of the RO system, while also offerin